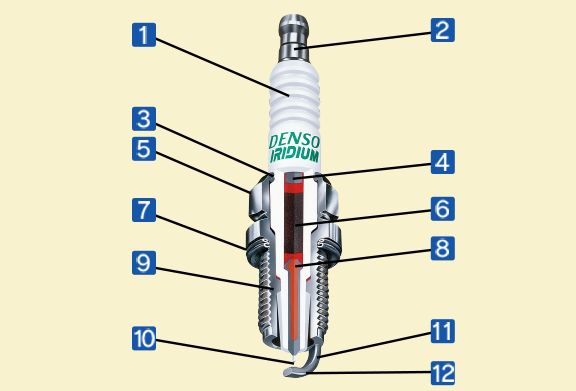

SPARK PLUG Construction

A spark plug comprises three main parts: the housing, insulator, and electrodes.

* Example: IRIDIUM POWER

Insulator

Insulator

Insulates the terminal, center shaft and center electrode from the housing, preventing escape of high voltage from the electrodes.

Since the bottom of the insulator projects into the combustion chamber, high purity alumina with superior heat-proof characteristic, mechanical strength, excellent insulation and thermal conductivity at high temperature, etc. is used.

Terminal

Terminal

The terminal is connected to a high-tension cord through which high-voltage current from the ignition system flows.

A terminal nut is installed so this type can support almost any high-tension cord in the world. For vehicles not requiring a terminal nut, the terminal can be removed.

Ring, packing washer

Ring, packing washer

Makes the insulator and the housing fit tightly to each other and maintains the airtightness.

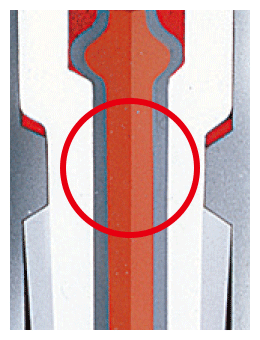

Center shaft (stem)

Center shaft (stem)

Center shaft connecting the terminal and the center electrode.

This shaft is made of steel and has the role of allowing high-voltage current to flow from the terminal to the center electrode without loss.

Housing

Housing

The housing forms an outer shell that surrounds the insulator, supports the insulator, and installs the spark plug in the engine.

At the bottom the ground electrode is located, so current can flow through the engine itself to the center electrode over the gap.

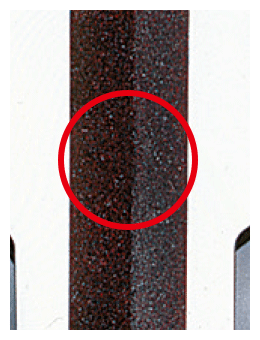

Glass Seal

Glass Seal

Mounted between the center shaft and insulator to maintain the airtightness.

DENSO uses the glass seal method.

A special mixture of glass powder and copper powder is charged in the installation section for the insulator and center shaft and center electrode and melted at high temperature. This bonds the center shaft and the center electrode and fuses the insulator and the metal.

The sealing for both is good and the thermal ratio of expansion is appropriate, so even under harsh conditions gaps do not occur and good airtightness can be secured.

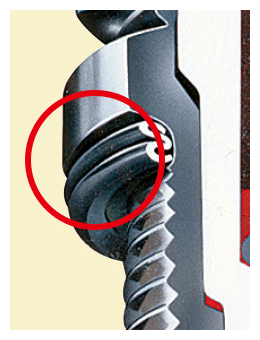

Gasket

Gasket

Makes the housing and the engine fit tightly to each other and maintains the airtightness of the combustion chamber.

There is a procedure for tightening and the appropriate tightening margin must be secured.

For details, refer to the information in “SPARK PLUG Installation”.

Electrode with copper

Electrode with copper

Special nickel alloy is used for the center electrode to reduce electrode wear.

Copper is sealed into the center section to improve thermal conductivity.

Ring, packing washer

Ring, packing washer

Makes the insulator and the housing fit tightly to each other and maintains the airtightness.

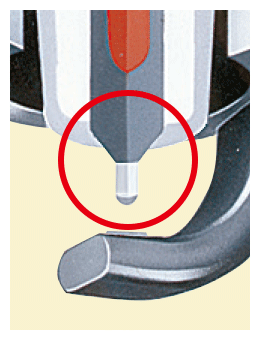

Center Electrode

Center Electrode

A new iridium alloy tip with a diameter of 0.4 mm is laser welded to the tip of the center electrode to make the center electrode.

This lowers the spark voltage, secure reliable spark, reduces the quenching effect, and improves ignition performance.

Iridium, like platinum, is a precious metal and has extraordinarily superior properties for a spark plug electrode, for example high-temperature withstand, high strength, and low resistance. In order to further improve oxidation resistance at high temperatures, DENSO developed a unique new iridium alloy containing rhodium.

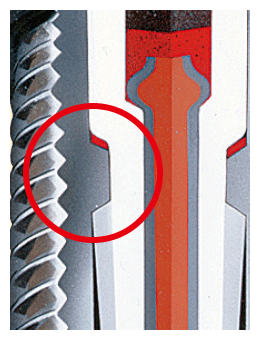

U-groove ground electrode

U-groove ground electrode

Nickel chrome material is used for the ground electrode and various measures are taken with the shape to improve ignition performance.

One of these measures is the U-groove.

(1) The surface contacted by the air-fuel mixture is large,

(2) There is much edge section, and sparks occur easily.

(3) The flame core (flame size) widens easily.

There are many other features as well and large ignition energy can be obtained.

DENSO obtained patents for spark plug U-grooves from 1975 to 1992.

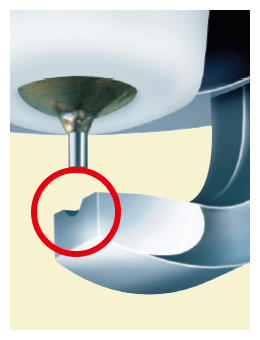

Tapered cut ground electrode

Tapered cut ground electrode

The ground electrode has a shape in which the electrode tip is cut to a finely tapered shape.

This reduces the quenching effect, so it improves ignition performance.